-

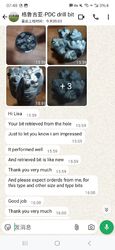

リタトリコーンビットの品質は良い

リタトリコーンビットの品質は良い -

グラム穴から取り出した 押しただけよ 動作が良かった

グラム穴から取り出した 押しただけよ 動作が良かった

API Special Tungsten carbide insert 9-7/8 " (250mm) Rock Mining Tricone Drill Bit

無料のサンプルとクーポンを私に連絡してください.

WhatsApp:0086 18588475571

ウェチャット: 0086 18588475571

スカイプ: sales10@aixton.com

24時間オンラインでサポートします

x| タイプ | Tricone穴あけ工具 | 使用 | オイル、ガス、ミニグ、掘削、水 |

|---|---|---|---|

| 材料 | ダイヤモンド、合金鋼、炭化タングストン | マシンタイプ | 穴あけ工具 |

| 処理タイプ | 鍛造、キャスト | 応用 | オイル、鉱業、ガスの岩訓練 |

| アドバンテージ | 高効率、高強度 | 使用法 | 石油,鉱山,ガス |

| 歯 | 炭化タングステンの穴あけ工具 | ベアリングの種類 | 密封された忍耐のローラー・ビット |

| ハイライト | Tungsten carbide tricone drill bit,9-7/8 inch rock mining drill bit,API special tricone drill bit |

||

API Special Tungsten carbide insert 9-7/8 " (250mm) Rock Mining Tricone Drill Bit

1 . Descriptions:

Tricone bit is a rock drilling Tool with tungsten carbide insert used on the rock oil mining water or oil well . This rock drilling tool is manufactured according to API specs which are the API certification products. . Tungsten carbide material is very ard material which hardness is only lower diamond in all the material . Comparatively the Diamond drill bit , Tungsten carbide drill bit price is lower. Tricone drill bit is called roller cone bit according to API standard . Tricone bit is used tungsten carbide material Tooth to cut the rock which are split two type roller cone bit welding TC Milled Tooth and TCI Inserted .TC Milled tooth and TCI inserted drill bit are customized Drill Bit according to the Rock grad. TCI Tricone bit is used for the middle hard to hard rock formation. Milled tooth (all called steel tooth) tricone drill bit is used for soft to very soft rock formation.

This drilling tool is widely used in the mining well (such as coal mines, copper mines, and other rare metal mines),water well , oil /gas well and geological prospecting .

2. Specification:

| BIT SPECIFICATIONS | |

| Diameter: | 9-7/8" ”(250.0mm) |

| Body Type : | Steel Body |

| Tooth Type: | TCI Tooth |

| Bearing : | Sealed Rearing |

| API Thread API Connection: | 6-5/8 API REG |

| IACD CODE : | 537 |

| OPERATION PARAMETERS | |

| Weight (Kg): | 62 KGS |

| RPM Range (rotary): | 130-40 |

| Weight on Bit(kN): | 156- 327 kN |

| Make Up Torque ( KN): | 9.5- 12.2 KN |

3 . Tricone Drill Bit Proilfe and Composition part :

![]()

![]()

4 . Bearing Types

There are primarily three types of bearing designs used in tricone drilling bits:

• STANDARD OPEN BEARING ROLLER BIT:

On these bits the cones will spin freely. This type of bit has a front row of ball bearings and a back row of roller bearings.

• SEALED BEARING ROLLERS BITS

These bits have an O-Ring seal with a grease reservoir for bearing cooling. The seals acts as a barrier against mud and cuttings to protect the bearings

• JOURNAL BEARING ROLLER BITS

These bits are strictly oil/grease cooled with nose bearings, O-Ring seal and a race for maximum performance.

![]()

5. Question :

What we should be pay attention on choosing the tricone drill bit ?

- IADC code passport

- TCI & Steel tooth options

- Additional tungsten carbide inserts on heel rows

- Tungsten carbide coating on cone bodies

- Diamond coated tungsten carbide inserts on the gauge of the cones

- Tungsten carbide inserts on the shirttail of the legs

- Additional central nozzle for cleaning cones

The tricone feature is that they come with their own passport as below :

- The specification of the cones

- The quality stamp signed by the person who made and checked the bit

- The recommended drilling parameters to get the best performance out of the bit:

- Bit weight

- Rotation speed

- Flushing volume

![]()

6. Which type of tricone you should choose ?

It depends on the geology you are drilling in and the diameters of the borehole you are drilling. The International Association of Drilling Contractors (IADC) have developed an easy use step system to choose the right tricone for your geology with additional features such as bit protection for longer production life and so on .

| How the API have classify the Tircone Drill bit IADC CODE ? |

| I ADC Codes - Digits The first three digits classify the bit according to the formation it is designed to drill and the bearing/seal design used. |

|

First Digit 1, 2, and 3 designate STEEL TOOTH BITS with 1 for soft, 2 for medium and 3 for hard formations. |

| 4, 5, 6, 7 and 8 designate TUNGSTEN CARBIDE INSERT BITS for varying formation hardness with 4 being the softest and 8 the hardest. |

|

Second Digit 1, 2, 3 and 4 are further breakdown of formation with 1 being the softest and 4 the hardest. |

|

Third Digit This digit will classify the bit according to bearing/ seal type as follows: |

| Standard open bearing roller bit Standard open bearing roller bit, |

|

air-cooled Standard open bearing roller bit with gauge protection which is defined as carbide inserts in the heel of the cone Sealed roller bearing bit Sealed roller bearing bit with gauge protection Journal sealed bearing bit Journal sealed bearing bit with gauge protection. |

|

Fourth Digit The following letter codes are used in the fourth digit position to indicate additional features: A. Air Application R. Reinforced Welds C. Centre Jet S. Standard Steel Tooth D. Deviation Control X. Chisel Insert E. Extended Jet Y. Conical Insert G. Extra Gage Protection Z. Other Insert Shape J. Jet Deflection |