-

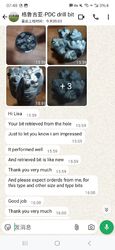

リタトリコーンビットの品質は良い

リタトリコーンビットの品質は良い -

グラム穴から取り出した 押しただけよ 動作が良かった

グラム穴から取り出した 押しただけよ 動作が良かった

8.5 インチ (215.9mm) M616 PDC マトリックス ボディオイル 井戸掘削ビット

| ハイライト | 8.5インチPDCマトリックスドリル,油井掘削 Pdcビット,M616 マトリックスボディドリル |

||

|---|---|---|---|

PDCドリルビット 適用別分類:

鉱業

オーストラリアやロシアで主に鉱業に使用される3刃PDCビットがあります. 形成は非常に柔らかいです. 鉄体PDCビットを選択すると,いくつかの掘削コストを節約できます.

水井の掘削

ROPが高く,ダイヤモンド型PDCのドリルは,地熱掘削のための水井のドリルとして広く使用されています.

石油・ガス採掘

- 石油・ガス掘削で最も広く使用されているビットです.水力要因は掘削中に非常に重要です.

- PDCビットは,以前は利用できなかった領域で使用されています. 例えば,より硬く,より研磨性があり,より変化する形状です.

- ダイヤモンド PDC ビットは主にビットボディ,切断歯,ノズル,ゲージ保護,APIスレッド接続で構成されています.

| IADCコード | M323 |

| 機体型 | マトリックスボディ |

| 刃数 | 6 |

| 主要切断器のサイズ | フ16mm |

| ノズル | N50 |

| API 接続 | 4-1/2インチ REG |

| 長さ を 補う | 278mm |

| 体重 | 80kg |

| 推奨されている操作パラメータ | |

| メイクアップトルク | 16-22 KN.M |

| 単位重さ | 22~112 KN |

| 回転速度 | 100 ドル |

| 流量 | 28~38 LPS |

カッター

ドリビットの主要な接触点は,ポリ結晶ダイヤモンド複合材料 (PDC) で作られたPDC切片です.

PDCビットは岩を切って効率的に除去します

困難な環境で動作する PDC 切断機は,井戸内で頻繁な加熱と冷却を経験します.

性能を最大化するために,優れた熱安定性と最小限の熱劣化を持つPDC切断機が好ましい.

これらの最適化された切断器は,より高い浸透率 (ROP) と強化された耐磨性を示しています.

ノズル

PDC 切断器の温度を維持し切断領域をクリアする上で,ドリルビットノズルは重要な役割を果たします.

PDC 切断機を冷やし 耐久性や性能を高めます

これらのノズルの位置と角度は,ドリルの有効性に大きな影響を与えます.正しく配置されたノズルは効率的な冷却を保証し,熱に関連する問題を防ぐのに役立ちます.

さらに,流体チャネルの戦略的な配置とノズルの位置は,掘削作業中に切片の改善を容易にする.

わかった![]()

生産プロセス:

![]()

認証:

![]()

わかった

パッケージと出荷:

![]()

![]()

FAQ:わかった

| Q: 貿易会社か製造会社ですか? |

| A: メーカー我々は100%本物の工場で 10年以上の経験を持つ 水/石油/ガス井戸のドリルビットです. |

| Q: あなたの製品はどうですか? |

| A:TriconeビットとPDCビットの両方が API 7の要件と ISO9001 に厳格に準拠しています. 我々は配達前に種類検査を行う,また,販売後のサービスをカバーします. |

| Q: パッケージ方法? |

| A: 通常は木製のケースで,また鋼製の箱でもあり,必要に応じてカスタマイズすることができます. |

| Q: 支払条件は? |

| A:私たちはT/T,L/C,Paypal,Western Unionなどを受け入れます. |

| Q: 私はあなたの工場を訪問できますか? |

| A: はい,私たちはあなたを歓迎します 私たちの工場にすべての時間,必要に応じて招待状を送信します.また,オンラインで私たちのワークショップと倉庫を表示することができます. |